As a professional factory with over 20 years of experience in the hotel textile industry, we have become a core supplier for many mid-to-high-end hotels thanks to our strong production capabilities and stringent quality control standards.

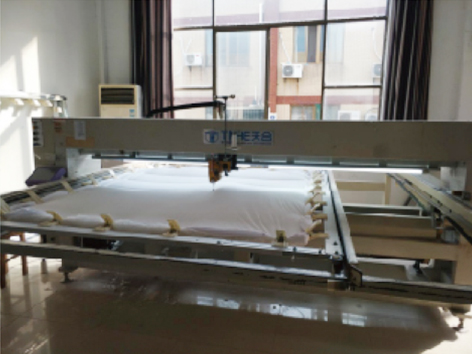

In terms of facilities, our factory boasts an 8,000-square-meter standardized production base equipped with 12 production lines, covering the entire process from fabric weaving and cutting to sewing and finished product inspection. We have imported German carding machines and Japanese precision sewing equipment, achieving a daily production capacity of 500 bedding sets and 2,000 comforters, efficiently responding to hotels' large-volume purchases and emergency replenishment needs.

Our technical team consists of 20 senior textile engineers who focus on the functional development of hotel linens. We optimize fabric formulas for high-frequency hotel use scenarios, developing all-polyester fabrics with 40% improved wrinkle resistance and moisture-wicking, quick-drying all-cotton fabrics, obtaining multiple utility model patents. Our quality control system spans the entire production process: from 36-point testing upon raw material warehousing to 7 inspection procedures during production, and final sampling sleep tests before finished products leave the warehouse, ensuring that every product meets international OEKO-TEX® eco-textile standards. We currently serve over 300 star-rated hotels, including international brands such as InterContinental and Marriott, and our annual linen supply accounts for 10% of the high-end hotel procurement volume in East China.

We are committed to "mass production without downgrading, and guaranteed customization," offering personalized services such as custom embroidered labels and size adjustments based on hotel needs. Coupled with our 72-hour rapid sampling capability, we create exclusive bedding solutions for hotels.

-

0+Rich Industry Experience(Years)

-

0+Factory Cover(㎡)

-

0+Daily Production Capacity(PCS)

-

0+Global Business Partner

-

Customer ServiceWhether it's cleaning frequency, laying efficiency, or inventory management, we always start from the actual needs of our customers and provide solutions that better meet their requirements.

Customer ServiceWhether it's cleaning frequency, laying efficiency, or inventory management, we always start from the actual needs of our customers and provide solutions that better meet their requirements. -

Integrity ManagementWe adhere to seeking truth from facts in core parameters such as material usage, yarn count density, and weight specifications.

Integrity ManagementWe adhere to seeking truth from facts in core parameters such as material usage, yarn count density, and weight specifications. -

TeamworkSufang Textile is a manufacturing enterprise that values the experience accumulation and craftsmanship proficiency of every frontline employee.

TeamworkSufang Textile is a manufacturing enterprise that values the experience accumulation and craftsmanship proficiency of every frontline employee.

-

Intensive in Manufacturing

Intensive in Manufacturing -

Innovative and R&D

Innovative and R&D -

Commitment to Quality

Commitment to Quality -

Global Partners

Global Partners

-

Optimizing Fabric Formulas01Optimizing Fabric Formulas

Focusing on optimizing fabric formulas for high-frequency usage scenarios in hotels.

-

Anti-wrinkle & Quick-dry02Anti-wrinkle & Quick-dry

Developed polyester fabric with a 40% improvement in wrinkle resistance and moisture absorbing quick drying cotton fabric.

-

Style & Durability03Style & Durability

Combines trendy colors, personalized patterns, and high-strength materials for visually appealing, long-lasting products.

-

OEM/ODM Service04OEM/ODM Service

OEM/ODM supported. Customize size, structure, material, logo, packaging, and functional modules based on your market needs.

We can customize bed linen using environmentally friendly materials (such as recyclable PC and RPET fabrics) based on customer requirements, meeting both environmental and personalized needs.

By optimizing production processes, we reduce material waste, lower our carbon footprint, and contribute to a greener supply chain.

English

English

Hotel Bedding Set

Hotel Bedding Set +86-180 6864 1189

+86-180 6864 1189 +86-(0)513 86311444

+86-(0)513 86311444

F Zone Chuanjiang Industrial Area, Tongzhou, Nantong City, Jiangsu Province, China

F Zone Chuanjiang Industrial Area, Tongzhou, Nantong City, Jiangsu Province, China